By now, we’ve probably all seen a few homes and yoga studios furnished with stunning bamboo floors. Yes, the bamboo is sustainably grown and the flooring is both durable and aesthetically pleasing. You might have also admired some attractive bamboo cabinetry. In fact, bamboo is common nowadays in all manner of interior construction, from floors to wainscoting to countertops. But what about bamboo in exterior construction?

Ongoing research and development have now made engineered bamboo for exterior construction a viable option, incredibly strong and impervious to the outdoor elements. Innovative, state-of-the-art technology that fuses bamboo with small quantities of phenolic resin and traces of ceramics results in a resilient construction material that’s suitable for decks, boardwalks and rooftops. At the same time, this engineered bamboo reduces the need for deforestation or the environmentally harmful production of steel and concrete.

Bamboo for green construction

According to a 2019 report from the United Nations Environment Programme, the construction industry is responsible for about 38% of CO2 emissions worldwide. Much of this is related to the production of concrete and steel, which are extremely energy-intensive and detrimental to the environment. Cleaner sources of energy are desperately needed, as are more eco-friendly systems and materials for building.

Natural and unnatural building materials

In terms of green construction, few things appear as promising as bamboo building materials. Side by side with concrete and steel, there is no comparison. Bamboo, like lumber, grows naturally from the earth and requires minimal processing. Like any plant that photosynthesizes, bamboo and trees absorb carbon dioxide as they grow and generate oxygen. This means they are carbon negative.

This capacity to remove carbon in the production stage will generally outweigh any carbon footprint resulting from the transportation and processing stages that convert these raw materials into commercially viable building material. In any case, the processing is relatively minimal compared to products like steel and concrete, which generate greenhouse gasses at every stage of production, from mining and refining to delivery and assembly.

Carbon negative, future positive

Tree-based lumber, of course, is nothing new, and is far more natural than other modern materials. But bamboo’s ability to capture carbon, create oxygen, and regenerate itself categorically surpasses any ordinary forest. Most evidence indicates that bamboo produces about 30-40% more oxygen than an equal area of trees. And when managed properly, this massive grass can store vast quantities of CO2 in its tenacious roots and rhizomes.

As a perennial grass, rather than a tree or an annual crop, mature bamboo can be harvested continually without killing off the plant. Roughly 20% of the bamboo can be harvested each year, once the grove is well-established, after 6 to 8 years. As it’s harvested, the plant grows stronger and is stimulated to produce more new growth. Like a lawn that’s been mown or a bush that’s been pruned, bamboo puts out new growth that’s stronger and more vigorous than before.

And because the plant itself survives, the carbon remains trapped in the biomass. And best of all, replanting is rarely necessary. Trees, on the other hand, can sequester a good quantity of carbon, but come harvest time, the carbon escapes from the roots and back into the atmosphere. Furthermore, new trees must then be planted, and it could take 20 to 30 years before the next harvest.

Assorted technologies for bamboo construction

Bamboo, like trees, has been around since time immemorial. Asians were building with bamboo at least a thousand years ago, probably much longer than that. While evidence of stone tools and stone construction remains for many millennia, bamboo breaks down quickly and won’t leave a fossil record. But we know that bamboo poles are extremely strong and versatile, as well as being lightweight and easy to work with.

Bamboo pole construction looks great in tiki bars and in tropical jungles. It has its limitations though. Because every pole is somewhat unique, it’s nearly impossible to build consistently on a large scale. Joints and corners can be tricky, too.

But with the advent of engineered bamboo lumber, beginning in the 1990s, the industry really began to flourish. And today, the level of innovation is more incredible than ever.

Standard laminate vs strand woven bamboo

Bamboo flooring and cutting boards first entered the US market around 1991, but it took another decade for them to really gain popularity. These early products were astonishing for their smooth texture and sleek appearance. The hardness of bamboo was also impressive, which is why it makes sense in floors and cutting boards.

Laminated bamboo remains a very popular material, now widespread in all sorts of housewares and consumer products, from cabinets and salad bowls to phone cases and toilet seat lids. If you look closely, you can see how strips of bamboo are lined up side-by-side and laminated. You can also admire the bamboo grain running horizontally and the intermittent nodes.

This kind of bamboo is impressive for its flat, smooth surface and its interesting wood-like grain. And we’re grateful that no trees had to give their lives to produce this lumber. Laminated bamboo also has a hard surface, stronger than many other kinds of wood. But unless it’s treated somehow, this type of bamboo is subject to water damage. The flooring always has a protective coating, but the bamboo kitchenwares, for example, are rarely dishwasher safe.

More recently, strand woven bamboo became available, revolutionizing our ideas about the incredible grass. Instead of simply aligning and laminating even strips of bamboo, the strand woven method actually crushes and compresses the bamboo.

As a result, the grain runs in various directions for even greater strength, and the material is about 50% denser than standard laminated bamboo. The finished product, therefore, is much harder and heavier. The extreme heat and pressure also make the wood darker, and the grain has an exotic, almost marble-like appearance.

With strand woven bamboo, the flooring got harder and more impervious to water. The possibilities for carpentry accents are almost unlimited. The material also produces some very attractive furniture.

Fused bamboo for superior building and exterior use

Just when we thought that bamboo building materials had reached their pinnacle, the Dasso Group introduced dassoXTR, fused bamboo for exterior use, a state-of-the-art product made with a proprietary, patented process.

Since 1993, Dasso has been a pioneer in bamboo flooring, furniture and construction materials. Perhaps the foremost producer of high-quality bamboo flooring and lumber, their products have become nearly ubiquitous. Dasso bamboo furniture is available at IKEA, and BMW uses Dasso bamboo in some of its dashboards. Dasso has even contributed to the construction of Spanish airports and Chinese opera houses.

Dasso’s latest innovation, however, takes bamboo lumber to an entirely new level. Always thinking outside the box, Dasso has been working with bamboo for outdoor construction since 2006. Created with a patented process, fused bamboo includes nanoparticles of ceramics and the same durable resins used in bowling balls, making it impermeable to the outdoor elements.

Two slightly different versions of fused bamboo are currently available, varying in color and contents.

Classic Espresso

Classic Espresso fused bamboo consists of 87% natural bamboo fiber and 13% phenolic resin, the same substance used in bowling balls. As the name suggests, this material has a very dark brown color. I’m not sure how you take your coffee, but this espresso is powerfully strong.

The lumber begins in the Moso bamboo forests of central China. Mature poles are harvested, cleaned and cut into strips. The nutrients, like sugar and starch, are then removed, and the strips are crushed, similarly to the strand woven bamboo process. Removal of the nutrients is key to protecting the bamboo from the elements, ensuring that it won’t attract bacteria, fungus, mold, or insects.

Under heat and extreme pressure, the bamboo is compressed to half its original size. In other words, it becomes twice as dense, twice as heavy. The density, in addition to a small amount of resin, creates an exceptionally hard and weatherproof building material.

Epic Cognac

Epic Cognac fused bamboo relies on most of the same methods and materials. The finished product contains 84% bamboo fiber and 13% phenolic resin, with the addition of 3% CeramiX® nanoparticles (basically, clay). The honey-brown color is the most obvious difference, but the nanoparticles significantly increase the hardness of the wood.

The main difference between Classic Espresso and Epic Cognac is that the sugar and starch are not extracted from the bamboo. Instead, the plant matter is impregnated with ceramic particles, which then crystalize with those natural nutrients. Ultimately, the process is very similar to how petrified wood is formed.

Because the bamboo nutrients crystalize with the ceramics, or clay, they are no longer attractive to molds and pests. This, again, makes the bamboo weatherproof and practically indestructible.

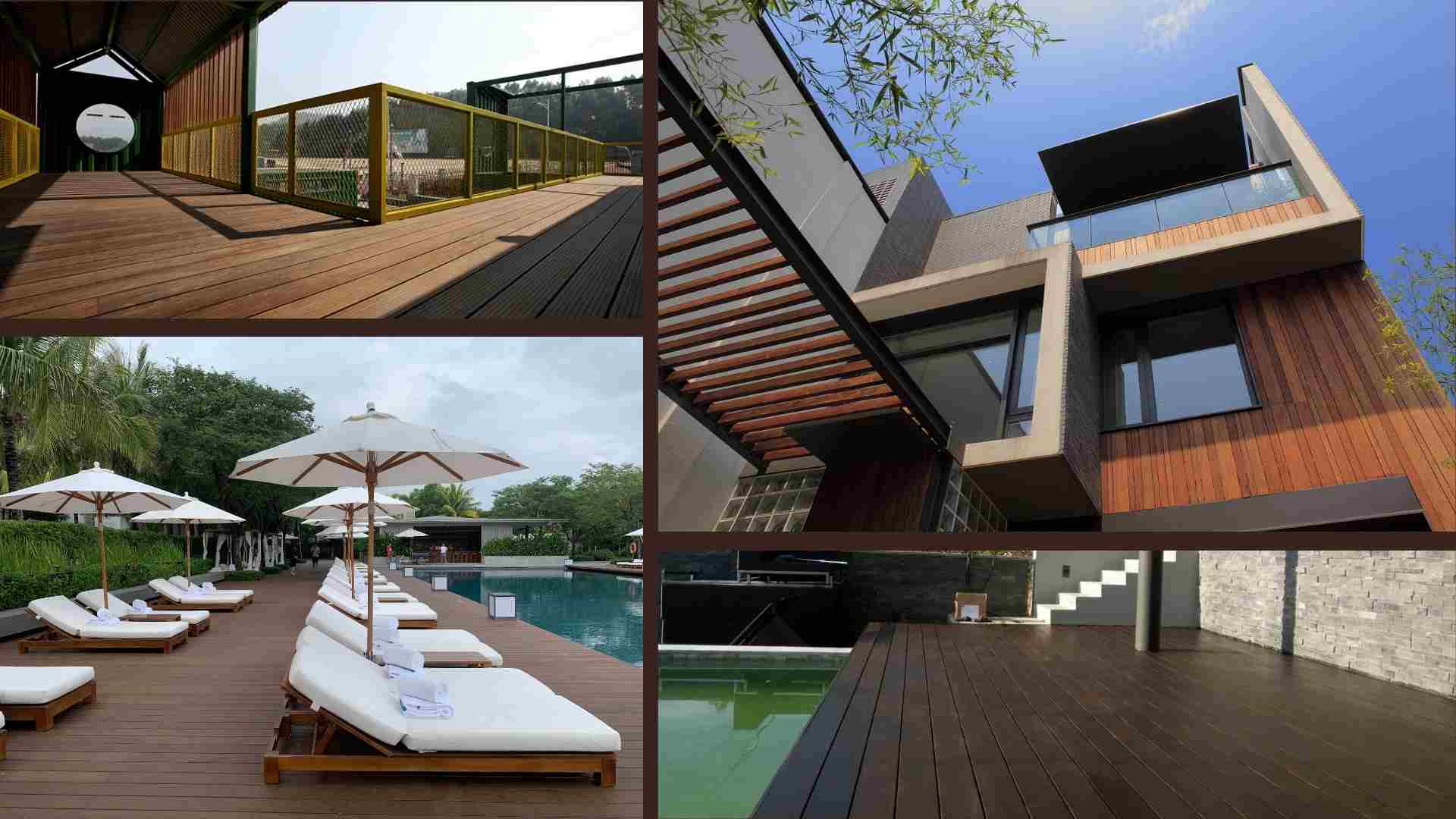

Bamboo applications for exterior construction

Up until now, engineered bamboo or solid bamboo, the kind used in flooring, kitchenwares, and so forth, has really been most suitable for indoor use. Strand woven bamboo can be pretty strong and weather-resistant, but fused bamboo is the first material of its kind that’s really intended for exterior use. As such, it opens up a whole new range of possibilities.

The fused bamboo comes in planks that use a tongue-and-groove system that is easy to assemble and install. The choice of espresso or cognac allows the option of a dark or light wood, but both are very attractive. You can even stain to the lighter cognac bamboo to achieve whatever shade your heart desires.

Perhaps the most popular use for this kind of bamboo is in outdoor decks and patios. Extraordinarily resistant against the weather, fused bamboo also works well in seaside boardwalks and piers. Choose between long slats and square tiles.

A wide variety of exterior accenting materials are also available. Bamboo RainClad siding is a hot item for both decoration and protection, commonly used on residential and commercial buildings alike. The inch-thick panels come in 6 or 7-inch widths and can be installed vertically or horizontally. Various trim and accessory pieces can also add a touch of style and sophistication.

Bamboo roofing is another possibility with this exceptional material. Fused bamboo is stable and durable; it won’t warp, expand or contract. Fence panels come in a few sizes as well, six feet long with varying widths.

Dasso has offices and authorized dealers all over the world. Check their website to find the one nearest to you.

Build up your knowledge

To learn more about using bamboo as an alternative and eco-friendly building material, take a look at some of these other in-depth articles.