Ever since I crafted my first set of nunchucks in junior high school, I’ve been in love with bamboo. This woody grass has a simple elegance to it. It grows faster than anything, and you can make anything out of it. I gradually outgrew my Bruce Lee phase — more or less — but my fascination with bamboo continued to flourish. I started making my own bamboo picture frames, and I bought my first bamboo cutting board. And then something amazing happened: I discovered bamboo clothing, and life was never the same.

Bamboo clothing and fabric first came on the market around 2001, with a remarkably soft texture that seems to combine the best of both silk and fine cotton. The new material promised to revolutionize the clothing and textile industry. Based on bamboo’s growth rate and renewability, the clothing is considered an eco-friendly alternative to pesticide-intensive cotton or petroleum-based synthetics. But the process of turning woody bamboo into soft fabric is less than perfect.

This article — first published in May 2007 and most recently updated in March 2024 — is part of a larger series about bamboo and natural fiber clothing and textiles. Peruse the Bambu Batu online library to learn more.

- How to care for bamboo clothing and fabrics

- Oeko-Tex Certification

- Why I love bamboo clothing

- Bamboo towels

- Bamboo sheets

- Bamboo vs. Hemp

- Hemp vs. Marijuana

Why bamboo clothing?

Conventional cotton is known to be one of the most pesticide-intensive crops on the planet, as it is susceptible to a number of pests. Particularly when grown in monoculture, cotton becomes the target of hungry boll weevils and a host of other small insects. And the defoliants used to strip cotton of its leaves before harvesting are some of the deadliest man-made chemicals available. They are closely related to the herbicide we commonly call Agent Orange.

Other synthetic fibers, like nylon and polyester, are derived from petroleum, and as such, they draw on fossil fuels and release microplastics. Of course, those pesky fertilizers, pesticides and defoliants are also products of the petrochemical industry. So freeing ourselves from these industrial fibers represents one more step toward liberation from fossil fuel dependency.

Today, most if not all bamboo clothing comes from Moso bamboo, which grows in great forests in China. In its native habitat, bamboo thrives without the need for pesticides or fertilizers. As a grass, bamboo can be harvested continually without the need for replanting. New shoots come up every year and reach their full height in a single growing season, which is about 60 days. And with Moso, that full height is close to 100 feet. In terms of renewability and sustainability, nothing comes close to bamboo.

In addition to bamboo, hemp and organic cotton also offer excellent alternatives to the highly-toxic conventional textiles. And, in fact, the future of sustainable agriculture depends not on a single panacea, but on a healthy diversity of alternatives. It’s true that we could make everything out of bamboo. But to monocrop the earth with anything, even bamboo, is no formula for a healthy, sustainable future.

It’s also important to realize that not all bamboo farms are equal. The grass can be managed responsibly or exploited in the name of maximum profits. For best results, you can look for products made from certified organic, FSC certified, or Oeko-Tex certified bamboo.

Unsurpassed comfort

Even if you don’t mind the presence of toxic pesticides and defoliants in the air and groundwater, it’s hard to resist the texture of bamboo fabric. For those who have never heard of it, the immediate reaction is not to think of bamboo clothing as soft. More likely, your mind will conjure up images of Fred Flintstone and his modern stone-age family.

To the uninitiated, bamboo underwear sounds like something terribly scratchy. And yet the soft touch of this material is as comfortable as anything you’ve ever worn. In some ways, bamboo is like silk, luxuriously smooth and draping gracefully. But it’s far more durable than silk, and also has the soft fluffiness of cotton. Furthermore, it spares the lives of innocent silkworms.

Bamboo socks are one of the most popular products. The material has some kind of antibacterial and antimicrobial properties that make it resistant to germs and odors. It’s also moisture-wicking and delightfully breathable. Soft and odorless, what else could your feet ask for?

Personally, I’m absolutely smitten with the bamboo towels. I’ve tried at least a dozen brands, and there can be a range of quality, but Daisy House Towels are my definite favorite. Some bamboo towels use 100% bamboo material, but they tend to be thinner, more delicate, and less absorbent. Daisy House uses a blend of 60% bamboo and 40% Turkish cotton. For absorbency and sumptuous softness, you won’t find a more wonderful bath towel. They also have dozens of colors to choose from.

When it comes to the pinnacle of luxury, bamboo bedding is where it’s at. For sheets, 100% bamboo is actually your best choice, for both comfort and durability. Luxuriously soft, bamboo’s breathability also makes the bedding excellent for temperature regulation. They literally do keep you cool in the summer and warm in the winter. After selling bamboo sheets for over a dozen years, this is what really amazed and delighted our customers, even more than the stunning softness.

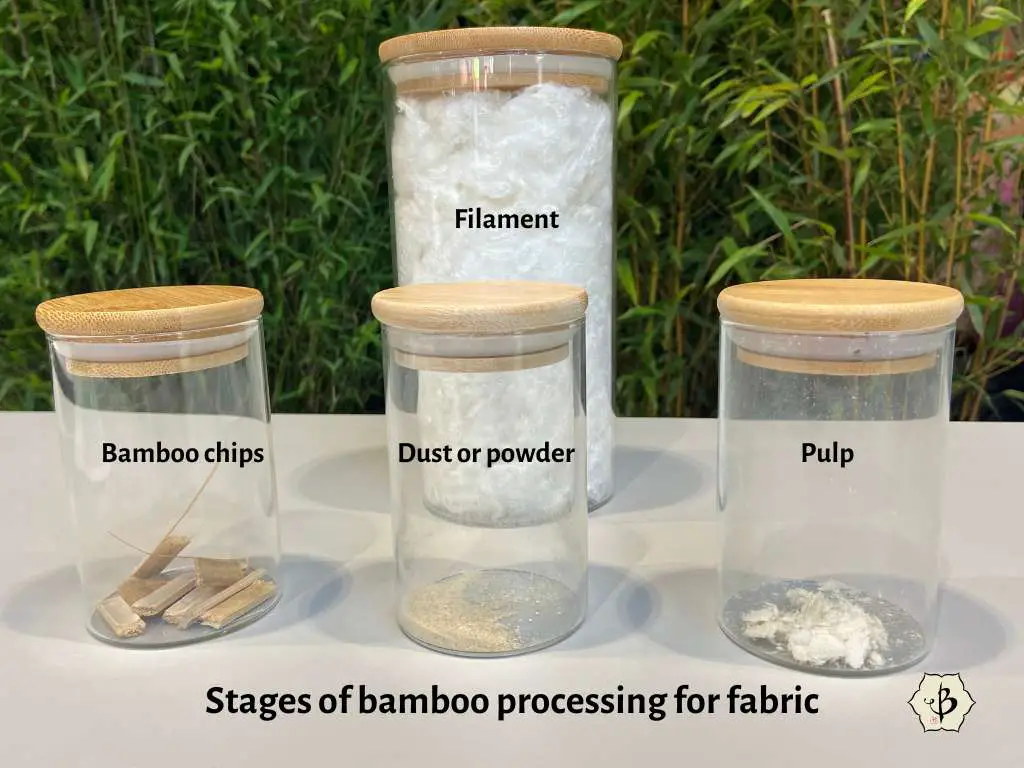

How do they make bamboo into clothing?

Turning a woody grass, harder than maple, into a soft textile, as sumptuous as silk or Egyptian cotton, sounds crazy. So how do they do it?

Basically, the bamboo stalks are crushed and pulped, and the plant cellulose is extracted and converted into rayon or viscose. Most rayon comes from tree pulp, like birch. Bamboo, like a tree, is high in cellulose. So the raw materials are natural and renewable. As described above, bamboo provides a far more renewable resource than trees. But the fibers that make up the yarns and textiles are manmade.

The process that takes wood or bamboo, turns it into pulp, and then reconstitutes it back into textiles (the xanthation-regeneration route), requires the use of an inorganic solvent, sodium hydroxide, commonly known as caustic soda or lye. It’s not the deadliest compound on the market, but you wouldn’t add it to your Kool-Aid.

Pros and cons of bamboo textiles

Like anything else, there are sloppy ways to produce rayon, allowing for excessive chemical runoff and irresponsible oversight. But there are also methods to close the loop and reduce waste to an absolute minimum. From my experience, running an all-bamboo boutique for a decade and a half, the great majority of companies involved in bamboo clothing production are doing it for all the right reasons. And they are committed to creating an eco-friendly product.

So is this the perfect material with zero ecological footprint? Certainly not.

But consider the advantages of not having to spray the crops with heavy chemicals. Also, cotton requires a tremendous amount of irrigation to cultivate commercially. And unlike other manmade fibers, bamboo rayon is not derived from petroleum. Furthermore, it does not shed microplastics into the environment every time you wash it. Polyester does, and so do those “eco-textiles” made from recycled plastic.

To the best of my ability, I perform my due diligence to learn everything I can about my bamboo clothing suppliers. Managing a retail business full-time, I never had the opportunity to fly to China and conduct factory inspections. But over the years, I developed very close relations with most of my vendors.

Quality bamboo clothiers

Yala Designs was probably our best-selling manufacturer, providing the lion’s share of our clothing inventory. They got into the bamboo clothing business early and set the standard for excellence, with the highest quality fabrics and the most pleasing designs. Moreover, they were always outspoken about their pledge to run safe, clean, socially and environmentally responsible factories.

Bamboo sheet maker, Bed Voyage, has also taken great care to qualify for the highest ratings and certifications, for green textiles and fair trade practices, which they proudly display on their website. Something else I love is that, unlike mainstream linen producers, Bed Voyage does not treat its bedding with formaldehyde, which the industry commonly uses to make “wrinkle-free” sheets.

These are just a couple of manufacturers I’m familiar with, after having worked with them for so many years. But there are many more brands out there with upstanding, reputable practices.

Bamboo Viscose vs. Rayon vs. Lyocell

Rayon and viscose are really the same thing, as described in the process above. In North America, rayon is the common term, but elsewhere they call it viscose. The name simply refers to manmade cellulosic fiber. It could come from trees or bamboo, but after processing, it’s impossible to tell what the original source was.

Lyocell, aka Tencel, on the other hand, uses a different process. Despite the great similarity between the fabrics — both are manmade, cellulose-based, and super soft — lyocell has distinct advantages in how it’s made. Instead of caustic soda, the lyocell system relies on the non-toxic organic compound N-Methylmorpholine N-oxide (NMMO). It may not roll off the tongue so well, but with NMMO, it’s easier to filter and reuse the solvent in a closed loop.

At this time, to my knowledge, not many bamboo clothing lines are using the lyocell method. The rayon process has become the standard in China, and a good deal of time and energy, from companies like Yala, have gone into refining this process to create better bamboo fabric. But it’s certainly an innovation we’d like to see more of.

Boody, based in Australia, has been producing an extensive line of bamboo underwear, shirts and leggings for close to two decades. Their fabulous bamboo garments are available around the world, and in 2021 they introduced a line of lyocell bamboo underwear, which they call Lyolyte. Boody uses only organically-grown bamboo, and they are a certified B-Corporation.

Ettitude is an example of a company specializing in bed sheets made from bamboo lyocell. They only recently showed up on my radar. I’m waiting for my first set of these sheets to arrive. I’ll be sure to let you know how they work out!

How to care for bamboo clothing and fabrics

Discovering this exotic new fabric, every customer wants to know what sort of special care bamboo requires. In fact, bamboo clothing is very easy to care for. Wash cold or warm and dry on low are the general recommendations. The material is every bit as durable as cotton.

Bamboo clothing does not require ironing or fabric softeners. The fabric softeners add more unnecessary chemicals, and in the case of bath towels, they also reduce the material’s absorbency.

If you’re interested in maintaining a more sustainable lifestyle, one of the most important things you can do is reduce your consumption. Take care of your clothes and make them last. Hot washing machines and high-heat dryers consume tons of energy, and for most people, they contribute the greatest wear and tear to your wardrobe.

For the smallest carbon footprint, and the lowest electricity bill, just hang the clothes on the line. Be aware, bamboo fabric does take a little longer to dry. So you may want to go for the compromise: dry on low for a few minutes, and then lay them out or hang them to finish. This also minimizes wrinkling, although wrinkling is not such an issue with bamboo.

But you’ll also notice that the colors don’t fade on bamboo clothing. The black t-shirts and leggings stay as black as ever, even after dozens of washes. Even so, you should still separate lights and darks before laundering. This is especially important with some of the very brightly-colored towels made from bamboo and cotton.

Further reading

Bamboo is an astonishing plant with unlimited potential. To learn more about bamboo textiles, be sure to check out some of my other in-depth articles.

- Why I love bamboo better than cotton

- How to wash and care for bamboo clothing

- Oeko-Tex and organic certification

- Hemp vs Bamboo: the ultimate comparison

FEATURED IMAGE: Fred Hornaday and friends modelling the classic “B here now” bamboo t-shirts, at Bambu Batu, California’s very first all-bamboo boutique.

Hi Fred,

Lovin the bamboo info, what a great renewable resource!

Thanks for the comment on my found art blog…and the name of the movie was “The Last Mimzy”…

Peace:)

Shauna

I have a question. is bamboo the same as tencel?

Bamboo fibres are gorgeous!

hmm, I have the same blog template…well, it’s a nice one 😉

I am a bamboo fiber aholic!!! I love anything bamboo fiber. It is soft, keeps you smelling good, and looks way more sophisticated then hemp (sorry Fred). I wish my whole wardrobe were made of this stuff it is the best!

Thanks, Rena. No need to apologize!

Yes, bamboo fiber clothing helps to build a healthy diversity. Apart from that, bamboo is eco friendly, uv protective and 100 % bio degradable. So, it supports the soil.

Thanks for the article, I was searching for the process of making cloth from bamboo even I am planning something, need to know more about the process.

I hope this article was helpful. There are some good explanations in the videos too.

Hello Fred,

I am currently interested in growing bamboo and hemp on my land. I want it to be versatile and have many uses. I live in the Midwest. Which would be a good bamboo to grow. I would like to use it for fabrics as well as for housing materials. Also I heard that household products can be made from them.

You can refer to this article on Bamboo Species for Farming. Most bamboo is versatile, but you will only have a raw material. Getting your bamboo to the factory and processed into pulp for paper or textiles will be the tricky part. You might focus instead on making something simpler like furniture, home decor, and crafts, for example: wind chimes, bird houses, planter boxes, musical instruments, etc