Given the measurable impacts of climate change and deforestation, the need for alternative building materials and energy sources has never been greater. That’s why bamboo, an incomparably renewable grass, is been touted as the sustainable solution. People have been building with bamboo for thousands of years, especially in Asia and South America where the big bamboo is most abundant. But the green building standards of today are taking bamboo construction to the next level.

Today’s green builders and architects can work with both natural bamboo poles and modern, engineered bamboo boards and beams. Nothing can come close to bamboo for renewability and sustainability, but cross-laminated and strand woven bamboo building materials are finally making bamboo construction a practical, scalable alternative. Cross-laminated and structurally engineered bamboo has all the strength and durability of the woody grass. But unlike ordinary and irregular bamboo poles, these materials are available in standard dimensions.

NOTE: This article first appeared in April 2021, most recently updated in May 2024.

The bamboo construction industry

Some of the oldest homes in human civilization were no doubt made from bamboo. And Asians have been using bamboo for scaffolding for as long as they’ve been building high rises in Hong Kong. But bamboo construction has come a long way in the last few decades.

Engineered bamboo is finally taking this miracle grass out of the straw village and into the suburbs. Think of the cozy huts from Gilligan’s Island compared to the solid bamboo cuttings where you can see the layers of bamboo stacked with the grain running in different directions. Of course, the Skipper’s quarters have their rustic charm. But for structural integrity and satisfying building codes, this modern, engineered bamboo is a whole other animal.

Cross-laminated bamboo

Cross-laminated bamboo, or CLB, is made from layers of bamboo pressed together, something like plywood. This is essentially what we mean by engineered bamboo. While the process involves a few more steps than simply strapping some poles together with a handful of thatching, the advantages are obvious.

When you harvest any species of bamboo, you will have an assortment of poles that are incredibly strong, but all slightly different in size. This makes it impossible to build multiple, standardized structures. CLB takes advantage of bamboo’s exceptional tensile strength and renewability, creating uniform beams and planks that architects and builders can rely on for large-scale projects with consistent results.

In addition to its better-known features, like being the fast-growing plant on earth with a structural strength comparable to steel, bamboo also has other benefits. CLB panels have remarkable insulation properties, which apply to both sound and temperature. This makes for homes that are not only greener to build but also more energy-efficient to heat in the winter or cool in the summer.

Also, check out our detailed article on Strand Woven Bamboo.

Sourcing engineered bamboo from around the globe

Like most bamboo products, the lion’s share of engineered bamboo is coming from China. Bamboo flooring, bamboo plywood, and bamboo cutting boards are almost exclusively made with Moso bamboo of Chinese origin.

In South America, especially Colombia, the local population has recently begun exporting its own formidable supply of Guadua bamboo. This giant timber bamboo has long held an important place in their culture. But now that the rest of the world is catching on to the greatness of bamboo, Colombians are recognizing its economic potential as an export crop.

In the interest of resource independence and smaller carbon footprints, Americans are also talking about farming bamboo. The will is there, and the farmland is available. What’s missing is the industrial infrastructure. If someone were to set up some factories to start processing engineered bamboo in the American South, it could be a genuine game-changer.

But at the moment, it’s something of a Catch-22. Factory investors are waiting for more farmers to plant bamboo, while the farmers are waiting for the creation of factories to purchase and process their bamboo.

BamCore: Sustainable Building Specialists

On the cutting edge of green construction and bamboo engineering, BamCore of Northern California has been fine-tuning its methods and materials for over a decade. They are committed to using the most sustainable materials available, and so they rely heavily on bamboo.

To minimize the carbon footprint from start to finish, they process their bamboo poles with a patented, low-embodied energy method that uses no heat, chemicals, or water. Then they use advanced building modeling software to minimize material waste and simplify the assembly process. Their unique panel system requires fewer studs, resulting in more hollow space with greater insulation.

Green Certification from NGBS

BamCore recently earned its Green Building Certification from National Green Building Standard (NGBS). The NGBS Green certification program is widely recognized throughout the industry for third-party assessments that scrutinize each manufacturer’s methods, materials, and affordability.

Cutting Edge Bamboo Tech from ReNüTeq

ReNüTeq has developed and implemented cutting-edge technology to produce some of the highest quality bamboo materials and the most state-of-the-art bamboo structures anywhere. The brainchild of St. Louis-based architect Luke D. Schuette, ReNüTeq has a number of patented technologies, including RadLam (Radial Laminated Bamboo) and LamStock, used in airport roofs, electric vehicle charging stations, and high-end residential construction.

Sourcing bamboo from around the world, but partial to Guadua bamboo from Latin America, ReNüTeq focuses on optimizing the highest performance fiber of the culm to create an Architectural Grade SEB (Structural Engineered Bamboo) that’s stronger than anything else on the market.

Plyboo: Bamboo boards, panels and flooring

PlyBoo is the name brand for a line of cross-laminated, engineered bamboo products from Smith & Fong. This industry leader started in Taiwan in 1989 and moved its manufacturing to China soon after. Today the company has its headquarters in San Francisco and produces many of its more specialized bamboo panels in the US. Most of the production still takes place in China, however, using Moso bamboo.

For over 25 years, Smith & Fong has been distributing Plyboo bamboo flooring in the US longer than any other company. They continue to innovate and develop new methods and technologies surrounding engineered bamboo.

A pioneer in bamboo building materials, they made one of their biggest breakthroughs in 2001, when they introduced bamboo strand flooring. As an alternative to laminating bamboo strips, this method involves crushing bamboo lumber and pressing it into dense logs. The result is an even harder material that is now commonly used in engineered bamboo boards and beams.

Problems with conventional construction

Conventional construction is one of the most polluting and carbon-intensive industries on the planet. Still, despite their contributions in generating such a great proportion of greenhouse gasses, the construction industry has been among the slowest and least responsive sectors in terms of innovation. Even compared to the agriculture, energy, and transportation industries, construction has been lagging behind.

Thankfully, a few vanguard enterprises like PlyBoo and BambCore are leading the way and developing better systems to bring green residential construction out of the fringe and into the mainstream.

Best bamboo species for construction

Bamboo is famously strong and fast-growing, but not every species of bamboo is equally useful as a building material. Generally, the largest timber bamboo varieties are the most desirable for construction, for pretty obvious reasons. But more important than the length and diameter of the poles is the thickness of the culm wall. Some bamboos are pretty big around, but they are thin and therefore vulnerable to cracking. And tropical bamboos tend to have stronger, thicker canes than temperate bamboos.

Genus Bambusa

One of the most widespread genera of bamboo, growing all across Asia and the Pacific Islands, Bambusa includes very useful species of tropical timber bamboo. In the Far East, Bambusa vulgaris, or common bamboo, has been cultivated for centuries as a cheap and easy-to-use building material.

Farmers in Africa have begun planting Bambusa balcooa and Bambusa bambos for the size and thickness of their culms. These resilient species are suitable for various African climates and provide a valuable building material.

Bambusa oldhamii is popular as an ornamental, and its giant culms are also practical for building.

Genus Dendrocalamus

Including some of the largest and strongest bamboo species of all, Dendrocalamus has tremendous economic importance in Southern Asia. Sometimes exceeding heights of 150 feet, Dendrocalamus sinicus is the biggest bamboo known to man, but very local to Southeast China and Laos. More widely grown and used in Indonesia, Dendrocalamus asper provides a low-cost but almost indestructible material for building and construction.

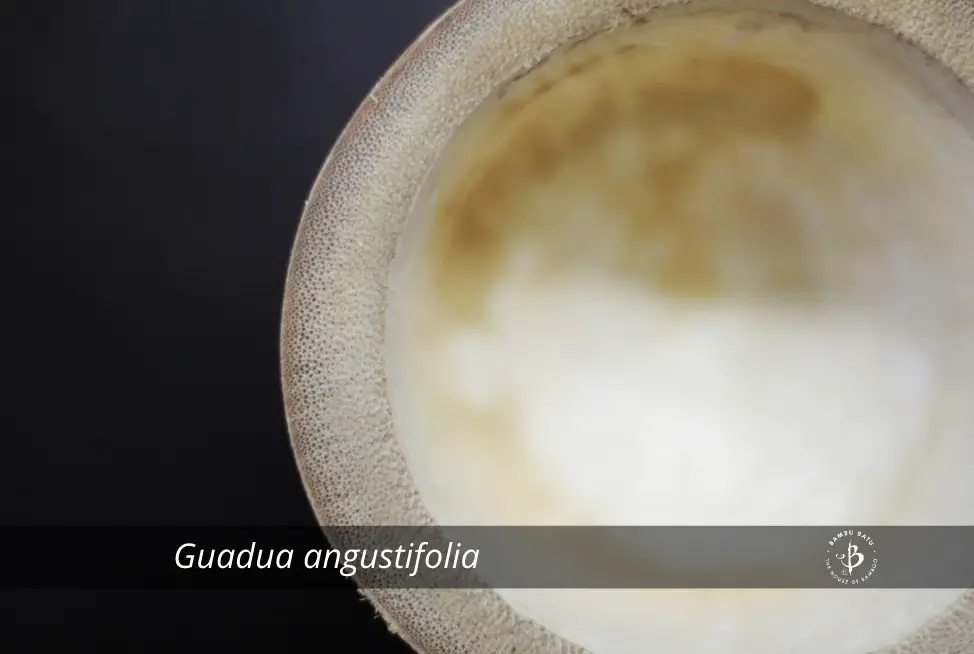

Genus Guadua

The most important bamboo variety in the New World, Guadua angustifolia comes primarily from the equatorial highlands of Colombia. This massive timber bamboo has provided an essential resource for thousands of years, and today they are using it for engineered bamboo materials.

For North American builders keen on using bamboo in their construction, engineered Guadua may be the best choice. The species itself has superior structural properties, but importing from South America also creates a smaller carbon footprint than shipping from Asia.

As Colombia exports increasing quantities of their bamboo, they are being incentivized to plant more and more of this long-revered crop. In this way, bamboo is improving both the local economy and the local ecology.

Genus Phyllostachys

These temperate running bamboos have proliferated around the globe, proving useful in industry as well as ornamental landscaping. Native to China, Phyllostachys edulis, or Moso Bamboo, must be the most economically important bamboo species on earth. Moso provides the raw material for all bamboo textiles, bamboo flooring, and the vast majority of engineered bamboo.

American farmers have planted a couple of Moso plantations in Florida and the Deep South, but results have been disappointing. Outside its native habitat, this species seems especially difficult to establish. Phyllostachys nigra ‘Henon’ (Giant Gray) and Phyllostachys bambusoides (Japanese Timber Bamboo) have proven better suited for North American growing conditions.

Learn more

If you enjoyed this article about bamboo construction and green building, you might also check out some of our other in-depth blog posts.

ReNüTeq has implemented patented technology that focuses on optimizing the highest performance fiber of the culm utilizing the highest performance species of bamboo in the world: Guadua sourced from Latin America is the largest and fastest growing, and is over 2 times stronger than any other bamboo species making ReNüTeq’s Architectural Grade SEB (Structural Engineered Bamboo) products the strongest natural resource for the building industry.

Amazing innovations you’ve accomplished. Keep up the great work, Luke!