If you are familiar with bamboo clothing, then you must know that it is sumptuously soft and incredibly comfortable to wear. And you might have noticed that bamboo clothing costs a little more than clothing made from conventional cotton or polyester. But bamboo is the fastest-growing plant on the planet. So if bamboo is such a remarkably sustainable resource, then why is bamboo clothing more expensive?

It seems surprising that clothing made from bamboo is more expensive than clothing made from slower-growing cotton and less sustainable polyester. But what we are looking at here are mass production and economies of scale. In other words, an increase in the level of production leads to a significant lowering of costs. Cultivation, processing and manufacturing of cotton takes place on an enormous scale compared to the “cottage industry” levels of production we have with bamboo. These scales and quantities of production have a far greater influence on the cost of a finished product than the simple rate at which the raw material grows.

NOTE: This article first appeared in July 2020, most recently updated in March 2024.

How expensive is bamboo clothing?

We love our bamboo shirts, our bamboo sheets and our bamboo towels. But it’s true that bamboo clothing and textiles are more expensive than conventional fabrics. Exactly how much more expensive is difficult to say, because it’s hard to compare apples to apples. But we can try to look at a few examples.

Bamboo t-shirts

A basic Onno® or Spun Bamboo® brand bamboo t-shirt typically sells for about $25. At Bambu Batu, we always sold our printed bamboo t-shirts for $30. These shirts are 70% bamboo and 30% organic cotton. Other bamboo manufacturers charge more. A silky soft bamboo shirt from Boody Wear® sells for about $40. A high-end men’s short sleeve shirt from Yala®, with 95% bamboo and 5% spandex, costs $60.

Compare that to a cotton t-shirt, and you could find a quirky design on a shirt rack from Target for about $5. A t-shirt from H & M is going to be more like $10 or $15. Go to a surf shop and you’ll probably spend more like $20 for a printed t-shirt with a cool print or a trendy logo.

So bamboo t-shirts generally cost a bit more. But for the comfort and softness, most people still think it’s a good value. If you’re used to buying shirts from Ross, Target or Goodwill, then bamboo shirts look pretty expensive.

But if you go shopping for a cotton t-shirt at Mr. Porter, you’ll see price tags from $50 to $100 or more. So there’s a lot more than just the content of the fabric going on here. And you could make similar comparisons with women’s bamboo dresses and skirts. Shop around a bit and the price range from store to store can vary dramatically, regardless of the material.

Bamboo towels and sheets

Again, it’s not easy to make an apples-to-apples comparison, because there’s a great range of prices for bamboo towels or cotton towels. If you go looking for cotton towels sets at Target or Costco, you’ll probably pay about $15-25 for a set that includes one bath towel, one hand towel and one wash cloth.

A three-piece set of bamboo towels could vary between $30 to $80. Our favorite towels from Daisy House, a blend of bamboo and Turkish cotton, sell for about $60 a set. But I’ve never touched a cotton towel at any price that could compare to these.

Bamboo sheets can run you anywhere from $80 to $500 for a queen set. Our bamboo sheets sets sell for about $160 and customer satisfaction is excellent. I’ve heard less favorable reviews of the $80 sheet sets from elsewhere, and the $500 sheet sets are said to be absolutely heavenly, but I haven’t tried them myself.

What are economies of scale?

The Industrial Revolution transformed society and elevated our species’ standard of living like nothing before. A big part of what was happening was the specialization and concentration of labor and industry to make production of ordinary goods astronomically more efficient. Rather than having a spinning wheel and a loom under each roof, where every family could spin their own thread and weave their own fabric, one hand-crafted garment at a time, factories came into being, producing standardized garments by the hundreds and thousands.

And so the age of capitalism and industrialization began. And if you’ve ever played the game Monopoly, you have a pretty good idea of what came next. Basically, the factories grew larger and the competition grew fierce. The titans of industry quickly realized that the best way to vanquish the competition was to out-size them.

Basically, larger factories and businesses have greater economies of scale. This means that manufacturing in larger numbers enables them to produce the same goods at a slightly lower cost. Essentially, this is the same mechanism that Wal-Mart uses when it moves into a town and drives the mom-and-pop shops out of business. Vast scales of production allow big manufacturers to undercut smaller dealers until they can no longer survive.

In time, the end consumer sees stores grow bigger and prices going down. So it’s hard to complain. But it also results in an uneven playing field where it’s exceedingly difficult for small manufacturers and speciality goods to enter the marketplace without being prohibitively expensive. This is essentially the same dynamic happening with mass-produced textiles and niche industry eco fabrics.

Cost and scale of bamboo production

The comfort of bamboo and its remarkable sustainability are what make the clothing a good value for most of our customers. But a lot of people think that bamboo should be less expensive since it’s so sustainable. Unfortunately, it doesn’t work that way.

Consider fossil fuel energy. Fossil fuels have to be drilled and extracted from the earth’s crust, then shipped around the globe in giant tankers, then highly refined to make fuel for cars or consumer plastics. And yet, in many places, a liter of bottled water is more expensive than a liter of gasoline.

Solar energy, on the other hand, is literally in the air we breathe. But it has taken decades of innovation and government subsidies to make solar power and electric cars even remotely competitive. It’s not because of the availability of the raw materials, i.e., crude oil and sunlight, but because of the scale at which these resources can be collected and processed.

According to The World Counts, the cotton industry produces 27 million tons of cotton each year, which they explain is enough to provide 27 t-shirts to each person on the planet. Cotton covers about 2.5% of the world’s arable land, and the Business Research Company says that the global cotton market amounts to approximately $64 billion a year.

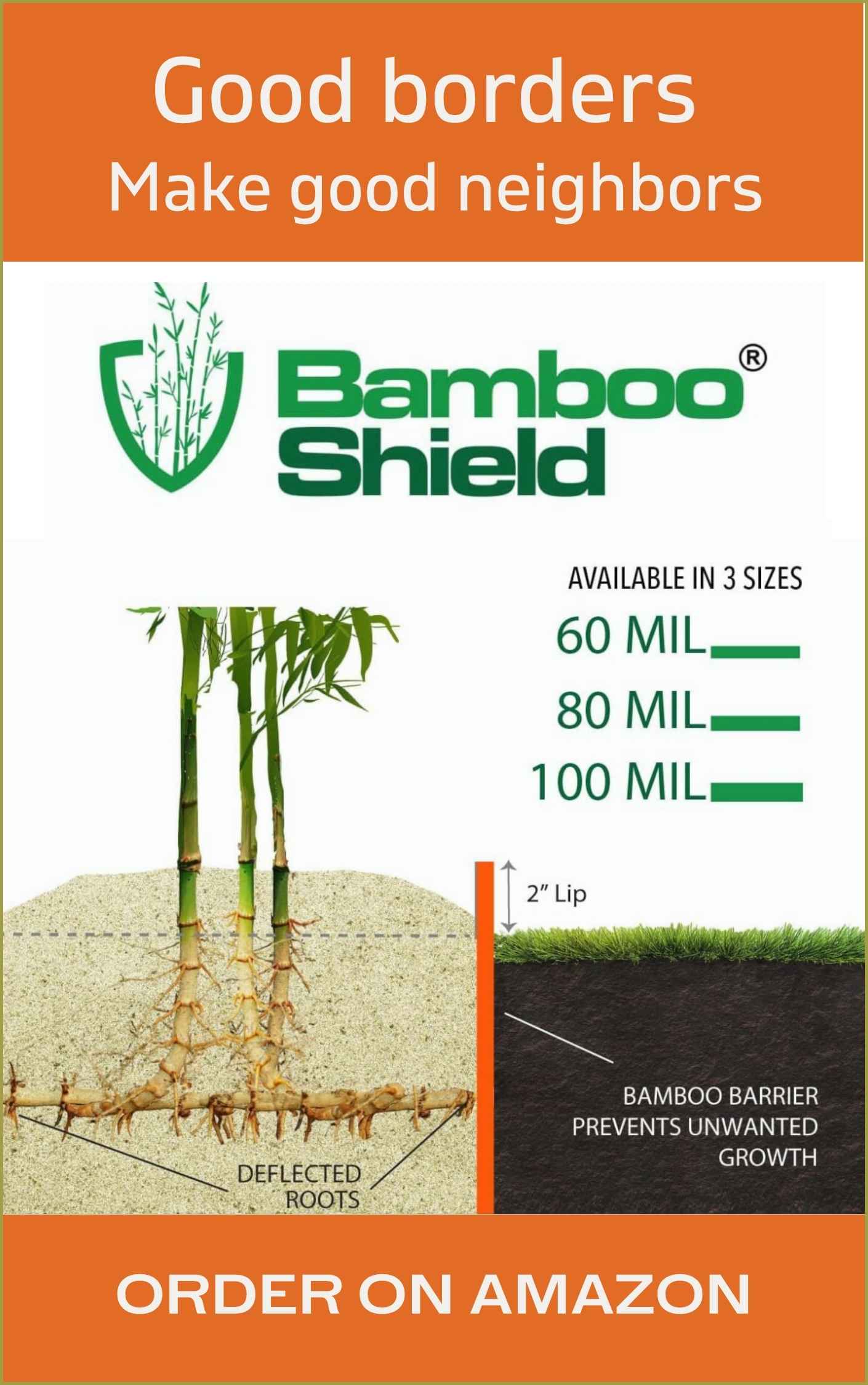

It’s hard to find statistics on how much of the earth is covered with bamboo, but it has a global industry of about $70 billion a year, according to Grand View Research, an online database and business consulting firm. That’s a lot of bamboo, but keep in mind, the majority of that bamboo is not being made into fabric. Of the bamboo that is not simply being sold as a raw material (plain bamboo poles), the great majority goes into flooring, furniture and other building materials.

Reliable and accurate figures about the size of the bamboo textile industry are difficult to obtain, but we can be certain that is is a small fraction of the size of the cotton fabric industry. Furthermore, the wheels of the cotton industry have been spinning for centuries, and an enormous international infrastructure is in place to ensure that this abundant fiber can get processed cheaply and efficiently. As such, newcomers like hemp and bamboo will have a very hard time competing.

Processing bamboo for fabric

In order to turn bamboo the grass into bamboo the viscose fabric that makes such wonderfully soft clothing, there is a chemical hydrolysis procedure that extrudes the cellulose from the plant tissue. This stage of production raises some environmental concerns for many, and rightly so. Although I think the quantity of chemicals and pesticides used for conventional cotton farming seems to overshadow the use of lye in processing bamboo.

This step of converting bamboo into fabric would also add to the overall production costs. However, the expenses incurred in this stage have less to do with the final cost than the issues of mass production and economies of scale described above.

Further reading

If you found this article about the cost of bamboo clothing useful and interesting, please consider sharing the link and subscribing to our blog. You might also enjoy some of the these other popular blog posts.

- Bamboo and carbon sequestration

- The benefits of bamboo

- Bamboo and ecology

- Common questions about bamboo

- The world’s 20 greatest bamboo gardens

PHOTO CREDIT: High-end bamboo dresses from Yala Designs